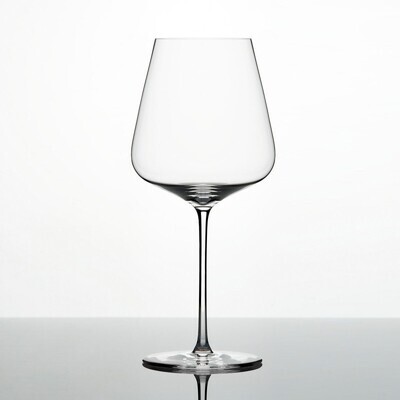

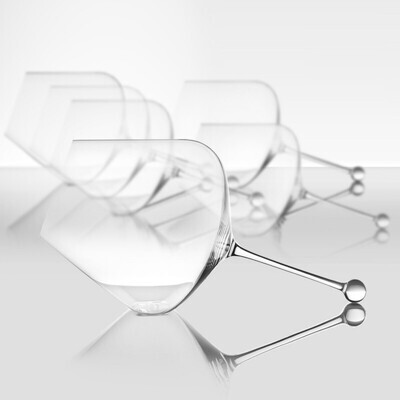

The roots of the company lie in the northern Waldviertel, where the glass tradition goes back to the early 14th century. The Zalto brand goes back to glassmakers from Veneto, who settled in this region. The forest belt, which stretches from Saxony over northern Bohemia and the Bavarian forest to the Carpathian Mountains, has always been a focus of European glass culture due to its range of raw materials. At the turn of the century, the region was home to over a hundred huts. The Waldviertel once housed 120 glassworks. Little by little the old craft came to a standstill. After the decline of the glass industry and the enormous challenges for manual production, we are continuing this tradition. The human component is by far the most important factor. Every part of the glass is made by hand with the help of the simplest tools, with a perfectly coordinated team of eight people dividing the various stages of work. With the exception of the bowl, which is blown into a mold, the glasses are created free-hand using the trained eye of the glassblower. Only the best master glassmakers in the world can produce glasses of this quality and level of execution. This requires years of training and practice. The delicate, thin-walled production of lead-free crystal glass in combination with a decidedly slow cooling phase after glass blowing ensure its high elasticity. In conjunction with a meticulous final inspection, in which all the glasses that do not meet the guidelines are melted down and recycled, the effort that is necessary for the creation of those masterpieces that bear the Zalto logo becomes clear.